Complete set of equipment for printing and dyeing wastewater

1, printing and dyeing wastewater characteristics

Textile printing and dyeing industry is a large discharge of industrial wastewater, wastewater containing mainly attached to the textile fiber of dirt, grease, salt of the machining process, and all kinds of slurry, dyes, surfactants, additives, such as acid and alkali.

Wastewater is characterized by high concentration of organic compounds, complex components, deep color and varied, pH changes, water and water quality change is large, it is difficult to deal with industrial wastewater. With the development of chemical fiber fabrics, silk and the rise of printing and dyeing finishing requirements raise, polyvinyl alcohol (PVA), rayon alkali solution material, and new dyes, auxiliaries and other difficult degradable organic matter into textile printing and dyeing wastewater, the traditional wastewater treatment technology pose a serious challenge, COD concentration is from the original hundreds of milligrams per liter rose to 3000 ~ 5000mg / L.

Dyeing wastewater with high colority, high COD, especially in recent years according to the foreign market development of mercerized blue, silk black, dark blue, deep blacks and other printing and dyeing process, the printing and dyeing extensive use of sulfur dyes, auxiliaries sulfide etc.. Therefore, wastewater containing large amounts of sulfide, the wastewater must be pre dosing treatment, followed by a series of processing, in order to stabilize discharge standards. Bleaching and dyeing wastewater containing dyestuff, size, surface active agent, this kind of waste water, concentration and chroma are low, if the simple use of physical and chemical processing, water is also in between 100 ~ 200mg / L, chroma also can to meet emissions requirements, but substantially increases the amount of pollution, the higher cost of sludge treatment, easy to cause the secondary pollution, under the current environmental requirements more stringent should give full consideration to the biochemical treatment system and conventional enhanced biological treatment process can meet the processing requirements.

2, design principles

The pollution source management and clean production, from the source control of wastewater discharge, reduce the production of pollutants and emissions;

1, the use of advanced, reasonable, mature and reliable processing technology and equipment for the characteristics of wastewater quality, the maximum possible investment benefit;

2, the use of efficient and stable water treatment facilities and structures, as much as possible to reduce the cost of the project, while combining the production of enterprises, the comprehensive treatment of sewage;

3, the use of more advanced control system, improve the automation level of sewage station, reduce labor intensity, to ensure continuous and stable operation of the sewage treatment system;

4, meet the requirements of the discharge standards, the use of advanced technology and energy-saving equipment, reduce operating costs of sewage treatment;

5, strive to the sewage treatment facilities layout is compact, process flow smoothly, as far as possible to reduce the number of sewage, as far as possible to save land;

6, the use of physical and chemical treatment based, supplemented by a combination of biochemical treatment process;

7, sewage treatment station operation is not caused by the surrounding environment two times;

3, water quality and water

Through the operation experience of similar wastewater, the relevant technical specifications and the local environmental protection department of wastewater treatment after the discharge requirements, the project's water quality indicators are listed as follows: 1:

project | CODCr(mg/L) | BOD5(mg/L) | SS(mg/L) | Chroma (Times) | pH | temperature0C |

Design water quality | 2000 | 400 | 300 | 150~200 | 8.0~9.0 | ≤40 |

project | CODCr(mg/L) | BOD5(mg/L) | SS(mg/L) | Chroma (Times) | pH |

emission standard | ≤80 | ≤20 | ≤60 | ≤60 | 6.0~9.0 |

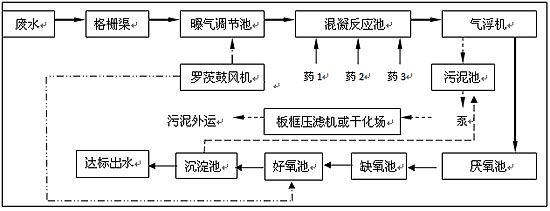

4, the principle of technology introduction

The sewage pipe collected by the sewage into the grid channel, the removal of water pump units may be blocked and the larger suspended solids after the valve into the aeration tank, in the aeration regulation of the average volume of the tank. In the aeration regulation pool at the end of the set of submersible sewage pump, the wastewater lifting entering the coagulation reaction pool, in mixed coagulation reaction tank through the dosing pump adding different medicament to the pool of different units in the, in under the action of the fungicides, water color, suspended substance to be removed. By mixing coagulation reactor treating the wastewater flowing into dissolved air flotation machine within suspended substance separation, flotation machine effluent into biochemical systems for removal of organic matter and ammonia nitrogen, water after biochemical precipitation reaches the draining standard.

Sedimentation tank discharge of sludge into sludge tank, and then through the sludge is pumped to the plate and frame filter press for sludge dewatering or drying field drying drying treatment.

5, process flow chart

6 main process unit

1, grille canal

The grid channel in the thickness of the stainless steel grille, used to remove the water pump unit may be blocked and pipe valve of the larger suspended solids, ensure that the follow-up facilities can operate normally.

2, aeration regulation pool

Whether industrial wastewater or domestic sewage, water quality and water content in the 24h are volatile. This change on wastewater treatment equipment, especially biological treatment equipment to play its normal purification function is unfavorable, and may even cause damage. Similarly, for the physical and chemical treatment equipment, water and water fluctuations, the more difficult the process parameters, the more unstable the treatment effect; on the contrary, the smaller the volatility, the more stable the effect. Therefore, in order to ensure the normal operation of wastewater treatment, the control pool is set up before the waste water treatment system to adjust the water quantity and the quality of the water.

The engineering design using aeration regulation pool, by pre aeration, can prevent deposition of solid material in the pool in settling down and anaerobic condition, and can oxidize reducing substances, stripping removal of volatile substances.

3, coagulation reaction pool

Coagulation reaction tank, carbon steel structure, internal corrosion treatment.

Ferrous salt is added to the first reaction tank unit and ferrous ions to their own as the center with dye molecules form polynuclear complexes, decolorization by complexation adsorption bridging mechanism.

The reaction pool second unit Ca (OH) 2, the formation of ferrous hydroxide floc sediment with ferrous ion..

Join the amide reaction pool of third units, the flocculent precipitate poly larger flocs synthesis good sedimentation performance.

4, dissolved air flotation machine

Sedimentation tank is mainly to remove suspended solids suspended in the wastewater.

This project is designed using dissolved air flotation machine, its removal effect is good, the treatment is stable, the plane layout is compact, the area is small. Air flotation machine using carbon steel structure

5, sludge tank

The sludge pool is mainly for sludge and flotation machine stored and concentrated in the settling tank discharge scum. A sludge pump is arranged in the sludge tank, and the sludge is transported to the drying field for dewatering.

6, anaerobic pool

Anaerobic pond is mainly used for the degradation of organic substances in water and a small amount of ammonia nitrogen.

7, anoxic tank

Removal of ammonia nitrogen from wastewater by denitrification in anoxic tank.

8, aerobic pool

The main function of aerobic pool is to remove organic matter from water by biofilm in aerobic tank.

9, sedimentation tank

The main function of the sedimentation tank is to make the SS to reach the emission standard.

Complete set of equipment for printing and dyeing wastewater 本文被阅读 1365 次