Flat film MBR device

A brief introduction to the device of flat plate membrane reactor

First, an overview

One of the unavoidable problems in the running process of MBR membrane is membrane fouling, that is, excessive deposition of activated sludge on the surface of the membrane, resulting in the decrease of the yield of the film. This issue is currently the country's MBR workers are committed to solving, hinder the development of MBR barriers. With the deepening of the research, materials technology is constantly updated and more and more engineering data, there may have been controlled by different membrane structure, aeration rate control, diaphragm spacing and regular cleaning method. The membrane structure mainly refers to the membrane component of the MBR reactor. The flat membrane has a large specific surface area, and can avoid the transition of the membrane surface in the environment of high sludge concentration, and can stably work under the condition of aeration and erosion for a long time. Membrane module is the core part of MBR, and the membrane configuration in the engineering application is mainly the hollow fiber membrane module and the membrane module. Flat membrane and hollow fiber membrane have different characteristics.

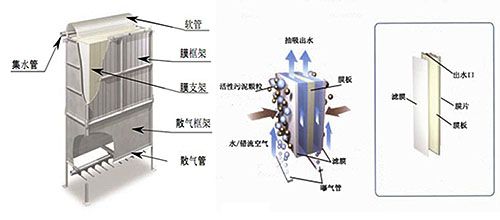

Two, flat membrane device structure

Three. Characteristics:

Membrane bioreactor (MBR) is the biggest feature is the use of membrane formation instead of the traditional process of the two settling tank for the clarification of the water. However, the seemingly simple one plus one, the effect is far more than two. MBR compared with traditional activated sludge method has the following obvious advantages:

(1) high concentration of pollutant removal rate is high, good effluent quality of MBR can be used for conventional activated sludge method is difficult to deal with, difficult to degradation of organic industrial waste water processing, and can be used for purification of domestic sewage and industrial wastewater. In MBR, due to the membrane module for the microorganisms in the reaction pool, especially for a longer period of time for a long period of nitrification and denitrification bacteria.

(2) the load changes to adapt to strong, impact load

Due to the high efficiency of membrane bioreactor membrane interception, the reaction tank hydraulic retention time (HRT) and the sludge retention time (SRT) are completely separated, even if the amount of water increases suddenly, the biological characters of the reactor can be maintained at a relatively stable state; at the same time, due to the increase of the concentration of sludge and strengthen the adsorption of activated sludge at the same time, the sludge concentration increased, enhanced the adsorption of activated sludge; moreover, the membrane interception, not by large particles biodegradation is not a rule with the water, can stay in the reactor slowly, until after the film was decomposed through discharge.

(3) small sludge discharge

The water treatment technology of membrane bioreactor can be used as an important technique to reduce the discharge of excess sludge as well as the advanced treatment of sewage and the technology of resource utilization. Usually used in conventional activated sludge method is biological cycle in a stable period to end the decline in the initial stage of the activated sludge, and due to the high sludge concentration in the membrane bioreactor, the total amount of microorganisms is very large, in consumption of organic pollutants in water and many micro organisms in the "hunger" state, so quite a part in the decline phase of microorganisms on the endogenous respiration metabolism decomposition, while maintaining a low concentration of pollutants in water at the same time consumed sludge amount remaining in the process of growth.

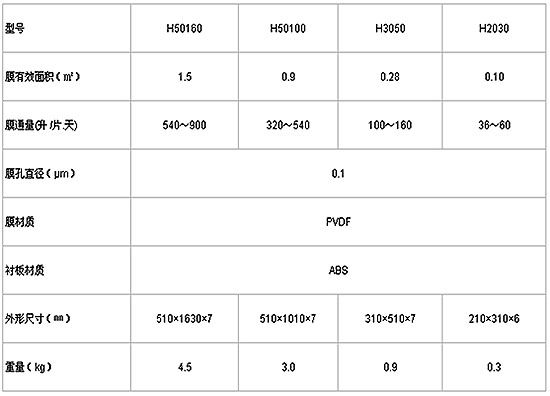

Four, MBR main specifications model:

Flat film MBR device 本文被阅读 1376 次