IC anaerobic reactor

1, overview

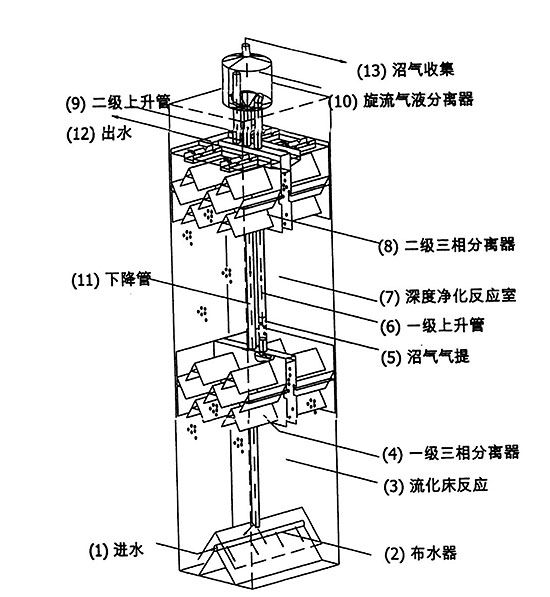

IC (circulation internal) reactor is a new generation of highly efficient anaerobic reactor, that is, the inner loop anaerobic reactor, similar to the 2 layer UASB reactor in series. It consists of two reaction chambers. Wastewater is flowing from bottom to top in the reactor, and the pollutant is absorbed and degraded by bacteria, and the purified water flows out from the top of the reactor.

2, working principle

It is similar to the 2 layer UASB reactor in series. According to the function division, reactor bottom-up is divided into five zones: mixing zone, the anaerobic zone, the anaerobic zone, precipitation area and a gas-liquid separation area.

Mixing zone: the slurry mixture in the bottom of the reactor, the granular sludge and the reflux of the gas-liquid separation zone are effective in this area.

First anaerobic zone: the mixture of mud and water mixture into the area, under the high concentration of sludge, most of the organic matter into methane. The sludge in the reaction zone was expanded and fluidized by the severe disturbance of the mixed liquid rising flow and the methane, which enhanced the surface contact of the sludge, and the sludge maintained high activity. With the increase of methane production, a part of the sludge mixture was raised to the top of the gas and liquid separation zone.

Gas-liquid separation zone: ascension is a mixture of biogas in this and mud water separation and derived processing system, slurry mixture is along the return pipe return to the lower end of the mixing zone, and the bottom of the reactor sludge and influent fully mixed, mixed liquid in the inner loop.

Second anaerobic zone: after first anaerobic treatment of wastewater, in addition to a part of the biogas was promoted, and the rest are through three-phase separator to enter the second anaerobic zone. The sludge concentration in this area is relatively low, and most of the organic compounds in wastewater have been degraded in the first anaerobic area, so the amount of biogas production is low. The methane gas is introduced into the gas-liquid separation zone through the gas pipe, and the disturbance of the second anaerobic zone is very small, which provides favorable conditions for the retention of the sludge.

The settling zone: the anaerobic zone of mud water mixtures in the precipitation area of solid-liquid separation, the supernatant to drain away from the water outlet pipe, the precipitation of the granular sludge return zone 2 anaerobic sludge bed.

From the working principle of IC reactor visible, reactor by 2 layers of three-phase separator to realize SRT> HRT obtained high sludge concentration; circulates through a large number of biogas and intense disturbance, the slurry full contact, good mass transfer effect.

3, equipment structure

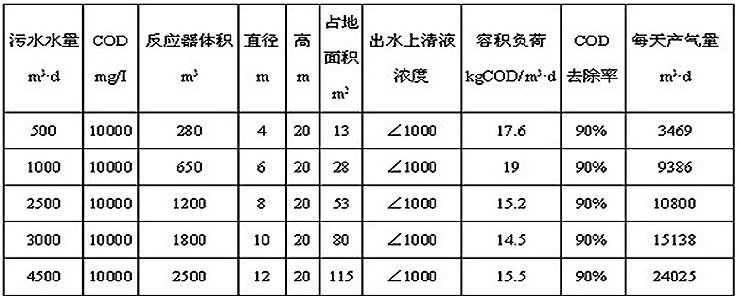

4, equipment parameters

5, the scope of application

IC anaerobic reactor is a kind of efficient multi internal recycle reactor, as the representative types of the second generation of the third generation of anaerobic reactor types represent (UASB anaerobic reactor), compared with the second generation anaerobic reactor, which has less land occupation, high organic load, impact resistant ability is stronger, more stable performance, operation and management more simple. The high concentration organic wastewater when COD is 10000-15000mg/1, the second generation UASB reactor is generally the volume load of 5-8kgCOD/m3; the third generation AIC anaerobic reactor volume loading rate of up to 15-30kgCOD/m3. IC anaerobic reactor is suitable for high concentration organic wastewater, such as corn starch wastewater, citric acid wastewater, brewery wastewater, potato processing wastewater, alcohol wastewater.

IC anaerobic reactor 本文被阅读 1424 次